|

| Centrifuge |

Our design is backed by detailed attention to operational convenience and safety. |

A centrifuge is the most energetic efficient machine for separating solid from liquid . The filtration types of centrifuge have a rotating basket, which supports the filter media with itself. The slurry is fed inside the rotating basket. Due to the centrifugal force the liquid is forced out through the filter media while the solid is retained inside the rotating basket . Hence generally, higher the centrifugal forces better the dryness of solids. A higher centrifugal force can be obtained by increasing the speed of the basket. |

| |

|

|

|

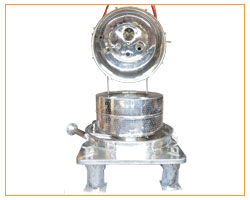

| FULL BODY OPENING Centrifuge |

|

| |

Our centrifuges are available in various models, sizes to suit customers requirements. |

| |

|

| Top Discharge with Manual Lid Opening |

|

|

|

| |

|

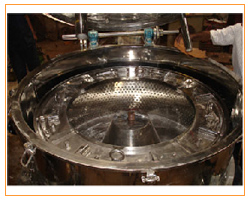

| Feed Pipe & Wash Pipe with Spray Nozzels |

|

SPECIAL CONSTRUCTION AND FEATURES: |

Machines made to “cGMP” |

Leak tests as Per DIN 24 400 |

Cleaning in Place-Spray Nozzles are strategically located to clean the machine internally

without Slaving to dismantle it. |

Feed monitoring device for efficient use of the volumetric capacity. |

Vibration Monitoring System for safe operation. |

Nitrogen Blanketing system |

Speed Monitor with Zero- Speed Interlock for safety of the operator. |

|

|

| |

| Drive Mechanisms: |

Lid Opening Device: |

Mechanical Clutch Pulley Mechanical Clutch Pulley |

Manual Manual |

Pneumatic Pneumatic |

Fluid coupling with reverse Current Braking Fluid coupling with reverse Current Braking |

Hydraulic Hydraulic |

Spring actuated Spring actuated |

Variable Frequency Drive with Dynamic Braking Variable Frequency Drive with Dynamic Braking |

|

|

| |

|

| Bag Lifting Type |

|

4 POINT MOUNTING MANUAL TOP DISCHARGE WITH PARTIAL OPENING LID |

One of the simplest type of centrifuge widely used in the industry.

The lids of centrifuge re manually opened out from the opening in the top of the basket.

|

ADVANTAGE OF MANUAL TOP DISCHARGE CENTRIFUGE: |

Manual removal of solids results in the total protection of crystal structure. |

Extremely simple operation. |

Very low solids loss in filtrate. |

Distinct separation between mother liquor and crystal. |

Enable better product quality. |

|

|

|

|

| Top Bag Lifting Type |

|

| Halar Coated Top Bag Lifting Type |

|

4 POINT MOUNTING MANUAL TOP DISCHARGE WITH PARTIAL OPENING LID |

One of the simplest type of centrifuge widely used in the industry.

The lids of centrifuge re manually opened out from the opening in the top of the basket. |

ADVANTAGE OF MANUAL TOP DISCHARGE CENTRIFUGE: |

Manual removal of solids results in the total protection of crystal structure. |

Extremely simple operation. |

Very low solids loss in filtrate. |

Distinct separation between mother liquor and crystal. |

Enable better product quality. |

|

4 POINT MOUNTING MANUAL TOP DISCHARGE WITH PARTIAL OPENING LID : |

Instead of partial opening lid, a fully opening lid can also be provided. |

It has the following advantages : |

More space for easy removal of solids |

Area between outer body and basket can be seen better access for cleaning. |

Easy in maintenance since the basket can be removed without dismantling the outer body. |

This lid opening can be opened easily using any of lifting mechanism, namely spring actuated, Pneumatic , Hydraulic. |

|

We can supply Lifting Bag Type Centrifuge Machine it has a full opening lid and a removable Basket top. To unload the solids, the entire bag is lifted along with the Basket top with the help of a hoist. This method of unloading the solids saves a lot of manual effort and time, the full opening lid excess the inspection and maintenance of the machine.

|

|

| |

| SUSPENSION /MOUNTING |

The centrifuge can be supplied with a 3-point pendulum suspension or the newer 4-point mounting. |

| |

| ADVANTAFGES OF 4 POINT MOUNTING |

Does not require elaborate or a heavy foundation. Does not require elaborate or a heavy foundation. |

Machine can be easily re-located. Machine can be easily re-located. |

Level of the vibration much lower. Level of the vibration much lower. |

Almost negligible maintenance cost. Almost negligible maintenance cost. |

Can be easily mounted on upper floors. Can be easily mounted on upper floors. |

|

|

| |

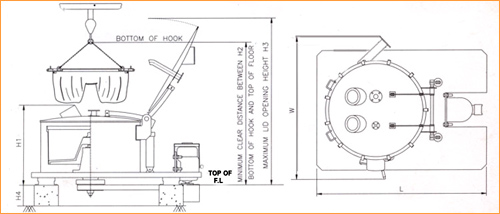

| DIAGRAMM |

| Data & Design subject to alteration |

|

| Sr. |

Details |

Units |

Model |

| LD 24" x 11" |

LD 36" x 18" |

LD 48" x 18" |

LD 60" X 20" |

| MTD |

MTD |

MTD |

MTD |

| 1 |

Basket Diameter |

mm |

610 |

914 |

1219 |

1525 |

| 2 |

Basket Height |

mm |

280 |

457 |

457 |

508 |

| 3 |

Basket Mouth Opening |

mm |

400 |

510 |

810 |

1000 |

| 4 |

Basket Speed |

RPM |

1400 |

1000 |

800 |

650 |

| 5 |

*Max. Perm Load |

kg |

45 |

200 |

295 |

525 |

| 6 |

Volume Under Lip |

litre |

45 |

200 |

295 |

525 |

| 7 |

Centrifugal Force |

G units |

665 |

508 |

434 |

358 |

| 8 |

Filtration Area |

m2 |

0.54 |

1.31 |

1.72 |

2.9 |

| 9 |

Motor |

|

|

|

|

|

| 10 |

Length (L) |

m |

1.5 |

2 |

2.5 |

2.75 |

| 11 |

Width (W) |

m |

1.1 |

1.65 |

2.1 |

2.15 |

| 12 |

Height (H1)-Lid Close |

m |

0.7 |

1.1 |

1.15 |

1.5 |

| 13 |

Height (H2)-Lid Open |

m |

1.5 |

1.9 |

2.1 |

2.5 |

| 14 |

Stand / Pillar Height (H3)-Minimum |

m |

0.3 |

0.4 |

0.45 |

0.45 |

| 15 |

Approx Empty Weight |

kg |

750 |

2300 |

4100 |

5600 |

|

|

|